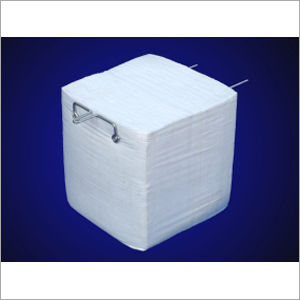

High Power Graphite Electrode

Product Details:

- Product Type Graphite Electrode

- Usage Industrial

- Color Grey

- Material Carbon

- Application Industrial

- Shape Oval

High Power Graphite Electrode Product Specifications

- Carbon

- Industrial

- Industrial

- Grey

- Graphite Electrode

- Oval

Product Description

We have carved a niche in the market as a famous organization engaged in manufacturing High Power Graphite Electrode. It is mainly used for the recycling of steel in the electric arc furnace industry. At our advance production unit, we prepare these electrodes using premium quality graphite. Engineered for efficiency and durability, these electrodes play a crucial role in electric arc furnaces for steel production and non-ferrous metal refining. With exceptional thermal conductivity and low electrical resistance, our electrodes ensure optimal performance in high-temperature environments. The robust construction, coupled with high mechanical strength, guarantees stability and reliability. Easily machinable for customization, these electrodes boast a long service life, minimizing downtime and maintenance costs.

Features of High Power Graphite Electrode:

- High power graphite electrodes exhibit exceptional thermal conductivity,

- It has low electrical resistance, ensuring optimal performance in high-temperature applications.

- Ensures consistent and reliable performance in electric arc furnaces

- Ideal for steel production, non-ferrous metal refining, and other high-temperature processes,

FAQ about High Power Graphite Electrode:

What is the role of high power graphite electrodes in electric arc furnaces?

High power graphite electrodes serve as conductive materials in electric arc furnaces, facilitating the generation of intense heat required for melting and refining metals.

How do I determine the right size of high power graphite electrode for my application?

- Electrode size depends on factors like furnace capacity, power requirements, and metal type. Consultation with a technical expert can help determine the appropriate electrode size for your specific needs.

What are the advantages of using high power graphite electrodes over other materials?

- High power graphite electrodes offer superior thermal conductivity, mechanical strength, and durability, making them ideal for demanding applications like steel production and non-ferrous metal refining.

How do I properly handle and store high power graphite electrodes to ensure their performance?

- Store electrodes in a dry environment to prevent moisture absorption. Handle them with care to avoid damage, and follow recommended storage practices to maintain their integrity.

What is the typical service life of high power graphite electrodes?

- The service life varies based on factors like operating conditions, furnace design, and electrode quality. Generally, high-quality electrodes can provide a longer service life, and routine maintenance practices can further extend their longevity.

Technical Indicators of Ultra high power graphite electrode:

| Items | Classification | Unit | Nominal Diameter (mm) | ||||

| High Power Graphite Electrodes HP | high power type II Graphite Electrodes | ||||||

| 200-400 | 450-500 | 550-600 | 350-400 | 450-500 | |||

| Resistivity | Electrode | μΩm | 7.0 | 7.0 | 7.0 | 6.5 | 6.5 |

| Nipple | 6.0 | 6.0 | 5.8 | 5.5 | 5.5 | ||

| Bending Strength | Electrode | Mpa | 10.5 | 10.0 | 10.0 | 10.0 | 10.0 |

| Nipple | 14.0 | 14.0 | 16.0 | 16.0 | 16.0 | ||

| Young’s Modulus | Electrode | Gpa | 12.0 | 12.0 | 12.0 | 14.0 | 14.0 |

| Nipple | 16.0 | 16.0 | 16.0 | 18.0 | 18.0 | ||

| Bulk Density | Electrode | g/cm3 | 1.62 | 1.62 | 1.62 | 1.64 | 1.63 |

| Nipple | 1.72 | 1.72 | 1.72 | 1.72 | 1.72 | ||

| CTE (100℃-600℃) | Electrode | ×10-6/℃ | 2.4 | 2.4 | 2.4 | 2.4 | 2.4 |

| Nipple | 2.2 | 2.2 | 2.2 | 1.6 | 1.6 | ||

| Ash Content | | % | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

Recommended current load of HP Graphite Electrodes:

| Grade | Nominal Dia. | Allowable current A | Current density A/cm2 |

| HP electrode | 200mm | 5500~9000 | 18~25 |

| 250mm | 8000~13000 | 18~25 | |

| 300mm | 13000~17400 | 17~24 | |

| 350mm | 17400~24000 | 17~24 | |

| 400mm | 21000~31000 | 16~24 | |

| 450mm | 25000~40000 | 15~24 | |

| 500mm | 30000~48000 | 15~24 | |

| 550mm | 34000~53000 | 14~22 | |

| 600mm | 38000~61000 | 13~21 |